Flexibility - Multipurpose machines

Solutions realized to be always capable to adapt to daily changes in the production.

Shape and dimension of the elements to be treated

Possibility to work in dry or wet conditions

Wide range of different surfaces available on the same machines

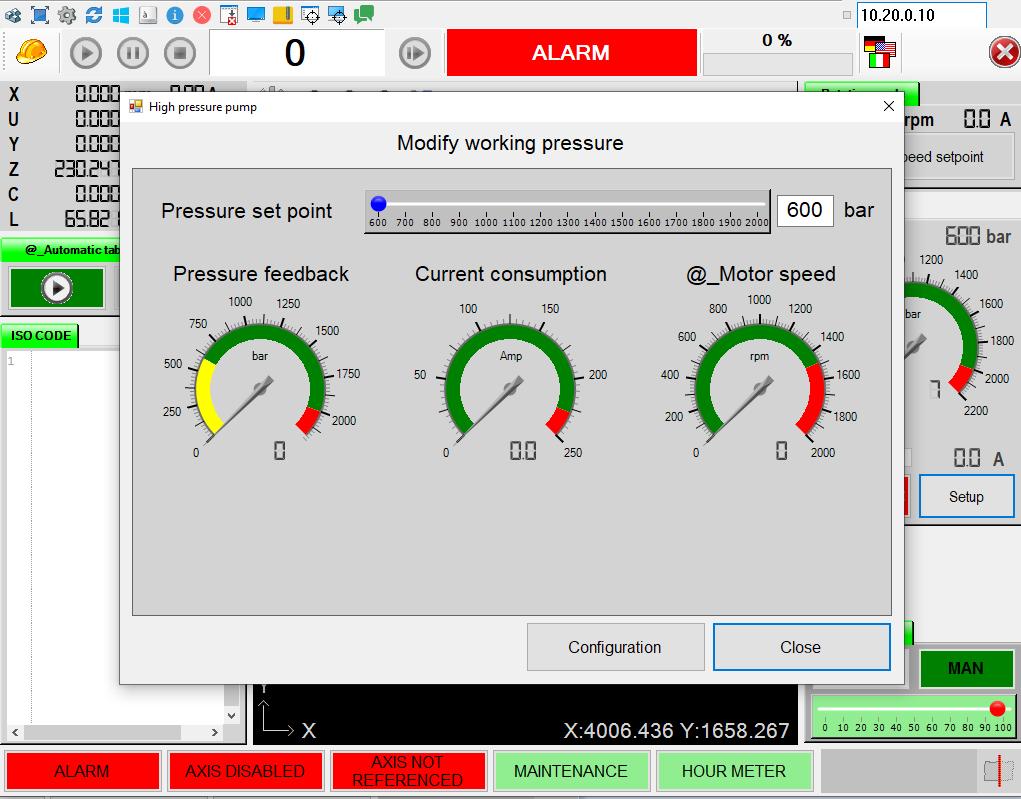

Friendly control systems

Thanks to the ultimate generation of control systems and the customized user interface always on PC base, the operators have the full controll of all the machine functions sometimes just with a touch.

Messages and comand described always in the customer’s language (other than the option to ask the help of the maema’s technicians trough a remote connections) makes always the operators confident.

On line reading systems

News

COVERINGS 2022, LAS VEGAS, April 5-8

MAEMA’S participation into the Italian pavillion organized by ICE

CONCRETE PAVING AND CLADDING

Technology: mechanical tools and water. Machine: surface treatment for small concrete elements and Stondeck.

KELLEREI ST. PAULS realized by Progress AG Spa

Technology: mechanical tools (bush hammering). Machine: surface treatment for big concrete elements.

HQ PROGRESS GROUP realized by Progress AG Spa

Technology: mechanical tools (polishing). Machine: surface treatment for big concrete elements.

MUSIC STUDIO, location Sweden

Technology: mechanical tools (polishing).Machine: surface treatment for big concrete elements.

Article on CPI ed 03-2021

Developed by the Italian company Maema Unipersonale, this new tool, enables the automated and rapid production of prefabricated concrete surfaces with complex graphic effects.

BAUMA 2022, October 24-30

As traditionally done since its born Maema has recognize Bauma as the most important event that put togheter people working in the costruction field and in particular for concrete.

MARMOMAC 2022, September 27-30

Maema it strongly linked to his territory as well as it is proud to reppresent even if in small portion the Made in Italy.